Frequently Asked Questions and Answers about Lost Wax Precision Casting Process

- Share

- publisher

- leena

- Issue Time

- Dec 28,2021

Summary

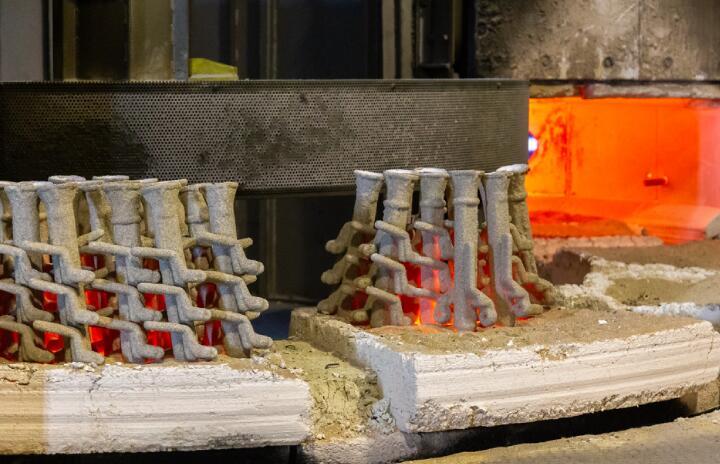

Frequently Asked Questions and Answers about Lost Wax Precision Casting Process

1.

Problem:In the lost wax casting process,the wax mold is not cleaned thoroughly, and the slurry cannot coat the wax mold well.

Solution: Use wax mold cleaning agent 7620#.

2.

Problem: In the casting process of stainless steel castings,the low quality of the wetting agent failed to reduce the surface tension.

Solution: use WET-10S wetting agent

3.

Problem: During the casting of brass precision castings, the slurry used for hanging slurry deteriorated, and the pH value was already lower than 9.5 at this time.

Solution: Constantly update to prevent paint deterioration or add paint guard GERM37.

4.

Question:Why does the shell mold of precision investment castings crack when the wind speed is too fast?

Reason: Because of the fast wind speed, the moisture on the surface of the shell mold will evaporate quickly and dry quickly, while the interior is still "wet". In this way, the strength of the dry and wet shell molds is different, and the shrinkage is not the same, causing cracks.

Solution: Control the air humidity during demolding

5.

Question: How to make the shell mold dry quickly without cracking during steel investment casting ?

The right process: During the steel investment casting process, the shell mold quick-drying strengthening agent SHELL WELL can be added to increase the drying speed and prevent the shell mold from cracking.