3D Printing for Manufacturing – Yes or No?

- Share

- Issue Time

- Jun 20,2022

Summary

3D printing is an interesting new development in the world of manufacturing. This tool has captured the attention of manufacturers as a way to reduce both time and cost, but the benefits and drawbacks vary depending on industry, project scope, and design.

3D printing is an interesting new development in the world of manufacturing. This tool has captured the attention of manufacturers as a way to reduce both time and cost, but the benefits and drawbacks vary depending on industry, project scope, and design.

Similar in practice to “lost wax” casting, this method uses 3D printing filament instead of wax to create the initial molds. Rather than melting the wax out of the molds, this method uses high heat to create “burnout” to disintegrate the filament within the mold. While 3D printing has the exciting potential to eliminate some of these disadvantages for smaller jobs, be sure to consider these three factors when considering 3D printing for a project vs mold making for your prototypes and investment casting:

- Material

- Part size & geometry

- Order volume

The Material

Although the 3D printing process generally speeds up prototyping, it’s not always true if you’re using stainless steel, titanium, or other metals. Using a traditional method of investment casting for prototype development will result in the same timeline as 3D printing in most cases, without the additional costs. Although additive manufacturing has come a long way, investment casting still remains the method of choice for industries such as aerospace, railway, firearms, and automotive.

Part Size and Geometry

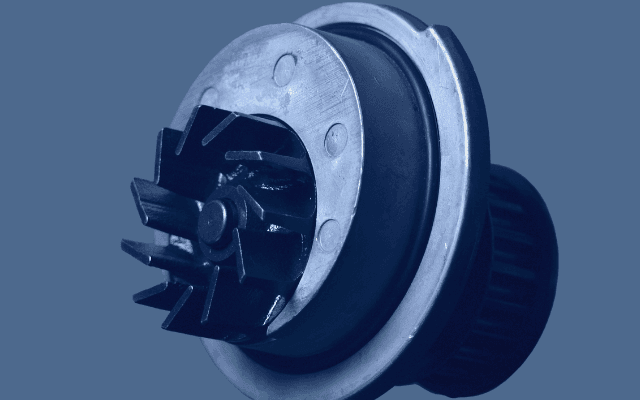

Both 3D printing and investment casting enables complex geometries for metal parts. For industries that rely on the engineering history behind investment casting, investment casting provides more reliability with a proven record of success.

Order Volume

Investment casting offers expanded metal material options over 3D printing and additive manufacturing, and better economics at scale. Additive manufacturing is relatively new, but since investment casting is well-understood and engineering expertise is more common, high-value and high-performance parts are still made with investment casting.

If you’re considering 3D printing for your next prototype but would like to take advantage of the reliability and cost-savings of investment casting, you don’t need to choose an “all-in-one” service provider. You can still reap the benefits of time and money with 3D prototype printing while using an expert casting foundry for your final production run. Foundries can use 3D printing for molds for wax injection and sand casting patterns, even if they don’t do the 3D printing in-house. Each situation is different, but if your project involves large metal parts or a high-volume order, perform a cost-analysis before you invest in 3D printing.

Contact us to find out how this groundbreaking new technology can help save you time and money on your next project.

OBT has always been a trusted partner in the foundry industry. We provide precision casting, die casting, sand casting, lost wax casting, forging and other processes. Surface treatment methods include sandblasting, chrome plating, dipping, hot dipping, surface hardening, powder coating, galvanizing, etc. Mainly used for auto parts, marine hardware accessories, railway transportation accessories, furniture hardware, machined parts and pump valves.