INVESTMENT CASTING

- Share

What Is Precision Casting?

Investment casting is one of the oldest metal forming processes in the world. For over 5,000 years the investment casting process has been used to create complex and detailed cast metal components for a variety of different applications.

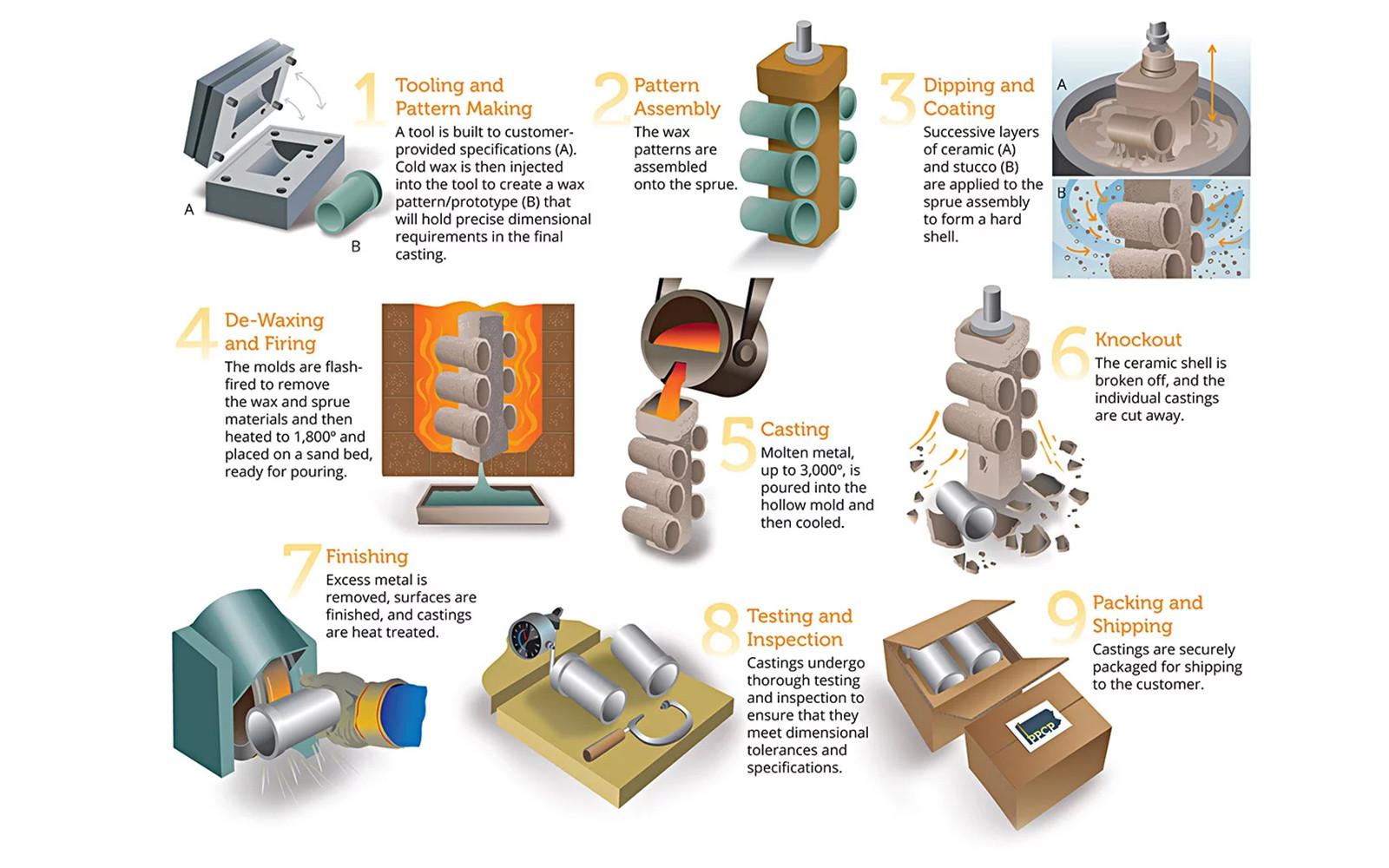

Metal castings are formed through the “lost wax” process. A wax replica of the component is produced, “shelled” and burned out to produce a mould for the metal casting. The desired metal is then poured into the mould and it is then left to solidify to form a finished casting. If you would like to learn more about the investment casting process, take a look at the step by step guide that we have created which explains the process in more detail.

The accuracy and quality that investment casting offers make it the first choice process for many engineers who work in industries where precision is paramount.

The investment casting process has many advantages. It can grant engineers a degree of design freedom and flexibility that cannot be matched by other traditional manufacturing processes. It can produce features that cannot be formed by machining and other traditional methods. The process can significantly reduce, and in some cases even eliminate, the need for expensive machining and assembly processes. The tight tolerances and fine surface finish that investment casting offers means that components can be produced that are fit for purpose in their ‘as cast’ state.

Investment casting is the ideal production method for manufacturing complex and detailed components that have to be lightweight and have good integrity.

How Investment Casting Works ?

Investment Casting is a manufacturing method that is used to produce a great variety of components for a wide range of industries. The investment casting process is sometimes referred to as the “Lost Wax Process” due to the role that wax has to play in the casting process.

At VLW we have over 20 years of experience manufacturing components through the Investment Casting process. We can produce castings from both Ferrous and Non-Ferrous metals at our Vietnam based foundry; we do so by carrying out the following procedure

What Factors Can Affect Precision Casting Quality ?

Usually, the dimension accuracy of precision casting parts is affected by casting parts structure, materials, mold, shell, casting and bake etc. any one of Link setting and unreasonable operation will change the contraction percentage of casting parts thus cause the deviation of casting part dimensions and precision requirement. the following factor will create accuracy defects of precision casting part dimensions:

(1)influence of casting part structure: a. the wall thickness of casting part is thick, contraction percentage large, the wall thickness of casting part is thin, contraction percentage small. b. free contraction percentage large, hinder contraction percentage small.

(2)The effect of casting materials: a. The higher the carbon content in the material, the contraction percentage of line is smaller. The lower the carbon content, the contraction percentage of line is bigger. b. casting contraction percentage of common material is as following: casting contraction percentage K=(LM-LJ)/LJ X 100%, LM is mold cavity dimensions, LJ is casting part dimensions. The following factor affect the K: wax mold K1.casting part structure K2.alloy type K3. pouring temperature K4.

(3)The mold affect for the casting part contraction percentage: a. the effect of shot wax temperature, Shot wax pressure, preservation pressure time on the size of the investment the most obvious is shot wax temperature, followed by Shot wax pressure. preservation pressure time has little effect for the final size of the fusible pattern after the guarantee fusible pattern forming. b. the contraction percentage of wax material about is 0.9-1.1%. c. when the fusible pattern is stored, it will produce shrinkage further and shrinkage value about is 10% of total shrinkage amount. but after 12 hours of storage, the investment size is substantially stable. d. The radial shrinkage of the wax mold is only 30-40% of the shrinkage in the longitudinal direction, and the effect of the wax temperature on the free shrinkage is far greater than the effect on the resistive shrinkage (the optimum wax temperature is 57-59 ° C, The higher the temperature, the greater the shrinkage).

(4)Influence of shell material: Zircon sand, zircon powder, Shangdian sand, Shangdian powder, because of its small expansion coefficient, is only 4.6×10-6/°C, so it can be ignored.

(5) Effect of shell roasting: Since the coefficient of expansion of the shell is small, when the shell temperature is 1150 ° C, it is only 0.053%, so it can be neglected.

(6) Effect of casting temperature: The higher the pouring temperature, the larger the shrinkage rate, the lower the pouring temperature and the smaller the shrinkage rate, so the pouring temperature should be appropriate.