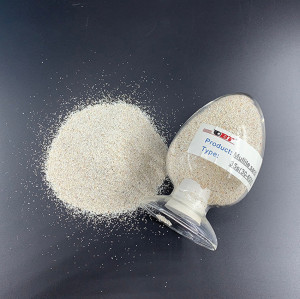

Industrial grade investment casting 22s sintered mullite sand

- Model

- OBTA-22S

Item specifics

- size

- 10-16mesh,16~30 mesh,30~60 mesh,200mesh,325mesh,et

- sample

- avaliable

- Refractoriness

- 1730℃-1750℃

Review

Description

Production Introduction and Application:

The mullite has high aluminum content, low iron content, small dust, reasonable particle size distribution, high bulk density, high temperature strength and low residual strength.

Available:10-16 mesh,16-30 mesh,30-60 mesh,60m,70 mesh,100 mesh,200 mesh,325 mesh.other sizes can be customized.

Mainly used in the aluminum smelting industry, refractory materials, precision casting , aluminum silicate refractory fiber and ceramic industry.

Specification of mullite sand

The Physical and chemical indicators |

||||||

Grade |

Fe2O3% max |

AL203% min | SiO2% min | TiO2% max | B.Dg/ccm min |

Refractoriness ℃ |

A Prime Grade |

1.20 |

46.00 | 50.50 | 0.70 | 2.55 |

1750 |

High Grade | 1.50 | 44.00 | 51.50 | 0.90 | 2.53 | 1750 |

Normal Grade | 2.30 | 43.00 | 52.50 | 1.00 | 2.50 | 1730 |

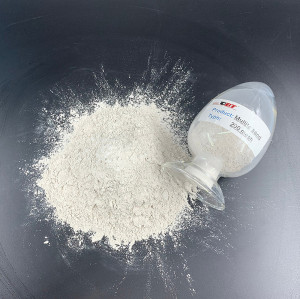

200mesh/325mesh | ||||||

200mesh/325mesh | 93%min | |||||

22S(16-30mesh) | ||||||

16-12mesh | 1.18-1.70mm | 25-35% | ||||

20-16mesh | 0.85-1.18mm | 40-50% | ||||

30-20 mesh | 0.60-0.85mm | <25% | ||||

50-30 mesh | 0.30-0.60mm | 0.02% | ||||

—50 mesh | 0.00-0.30mm | 0.04-0.06% | ||||

35S (30-60 mesh) | ||||||

50-30 mesh | 0.30-0.60mm | 65-75% | ||||

80-50 mesh | 0.18-0.30mm | 1.00% | ||||

—80 mesh | 0.00-0.18mm | 0.04-0.06% | ||||