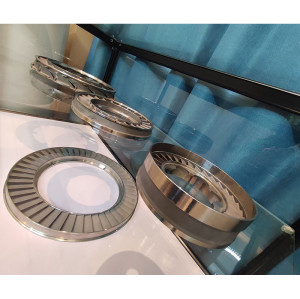

Custom Inconel Alloy Equiaxed Crystal Turbine Blades Nickel Alloy Titanium Casting OEM ODM Support

Item specifics

- Material

- Inconel Hastelloy Incoloy Monel

- OEM & ODM Services

- Available

- Weight

- Custom

- Tolerance

- 0.004mm

- Smooth surface roughness

- Ra0.6-3.2

Review

Description

The main functions and characteristics of the Equiaxed Crystal Turbine Blades include:

Equiaxed crystal turbine blades stand out as a fascinating engineering solution for high-temperature and high-stress environments. These blades, known for their distinctive microstructure, provide unique advantages and are different from other turbine blade types, such as single crystal blades. Here's a closer look at equiaxed crystal turbine blades:

1. Crystal Microstructure: Equiaxed crystal blades possess a grain structure with randomly oriented crystals. This is in contrast to single crystal blades, which have a specific crystal orientation. The presence of these grain boundaries in equiaxed blades grants them particular mechanical properties that are advantageous in various applications.

2. Versatility: One of the key advantages of equiaxed crystal blades is their versatility. Unlike single crystal blades, which excel in specific high-temperature conditions, equiaxed blades offer an attractive compromise between performance and cost. They are employed in scenarios where slightly lower temperature capabilities are acceptable.

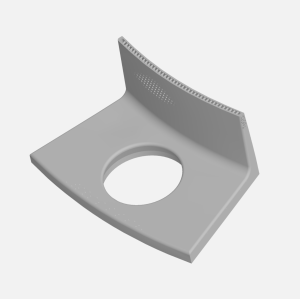

3. Manufacturing Process: Equiaxed crystal blades are typically manufactured through investment casting, a process that involves the production of intricate blade shapes. During the solidification process, the random orientation of grains forms the equiaxed microstructure.

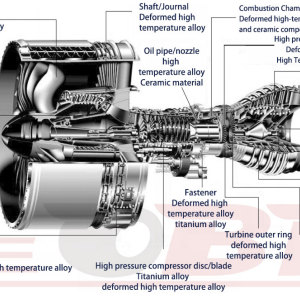

4. Applications: These blades find application in a wide range of gas turbine engines. They are commonly used in the low-pressure and mid-pressure stages of turbines in commercial and military aircraft, power generation facilities, and industrial machinery. Their ability to withstand high temperatures and mechanical stress makes them vital components in these environments.

5. Grain Boundary Effects: The grain boundaries in equiaxed crystal blades are points of both strength and vulnerability. While they contribute to the material's toughness, they can also be sites for crack initiation under extreme conditions. Understanding and managing these grain boundaries is crucial for optimizing blade performance and longevity.

6. Improved Reliability: Equiaxed crystal blades offer excellent reliability. Their unique grain structure imparts a balanced set of mechanical properties, making them a preferred choice for many applications where the demands are high but not extreme.

In conclusion, equiaxed crystal turbine blades are a distinct and versatile solution, providing a well-rounded balance between cost, performance, and reliability. Their random grain structure, in contrast to the highly ordered single crystal blades, gives them a special place in various industries that rely on high-performance turbine engines.