Custom Compressor Bearings Nickel Alloy Titanium Inconel 600 625 Casting OEM ODM

Item specifics

- Material

- Inconel Hastelloy Incoloy Monel

- OEM & ODM Services

- Available

- Weight

- Custom

- Tolerance

- 0.004mm

- Smooth surface roughness

- Ra0.6-3.2

Review

Description

Compressor bearings are essential components in various mechanical systems, including gas and steam turbines, air compressors, and refrigeration systems. These bearings are designed to provide support and reduce friction between rotating components within the compressor. Here are some key points regarding compressor bearings:

Function: Compressor bearings serve several important functions within a compressor system:

Load Support: They support the axial and radial loads generated by the rotating components, such as the rotor or shaft. This support is crucial for maintaining the stability and alignment of the compressor.

Friction Reduction: Bearings reduce friction between moving parts, minimizing energy losses and wear and tear. This is especially important in high-speed compressors, as lower friction improves energy efficiency.

Vibration Damping: Compressor bearings can help dampen vibrations, reducing the risk of mechanical damage and ensuring smoother, quieter operation.

Alignment Maintenance: They help maintain the proper alignment of rotating components, ensuring optimal compressor performance.

Types: Several types of bearings are used in compressors, including:

Ball Bearings: These contain rolling balls between the inner and outer raceways. They are commonly used in low- to medium-load applications.

Roller Bearings: Roller bearings use cylindrical or tapered rollers to support radial and axial loads. They are suitable for high-load applications.

Thrust Bearings: Thrust bearings are designed to handle axial loads and are often used in conjunction with radial bearings to accommodate both types of loads.

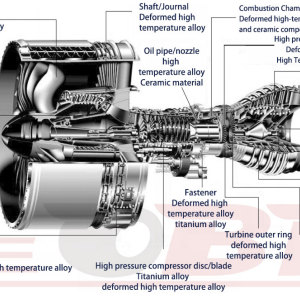

Materials: Compressor bearings are typically made from high-strength materials, such as chrome steel, stainless steel, or specialized alloys. The choice of material depends on factors like the compressor's operating environment, load, and temperature.

Lubrication: Proper lubrication is crucial to reduce friction and wear in compressor bearings. Lubricants are chosen based on factors like operating speed, temperature, and the type of load. Oil and grease are commonly used lubricants in these applications.

Maintenance: Regular maintenance is essential to ensure the longevity and reliability of compressor bearings. This includes lubrication, inspection for wear or damage, and replacement when necessary.

In summary, compressor bearings play a vital role in supporting and facilitating the smooth operation of various compressor systems. Their selection, design, and maintenance are critical to maintaining performance, efficiency, and reliability in these mechanical systems.